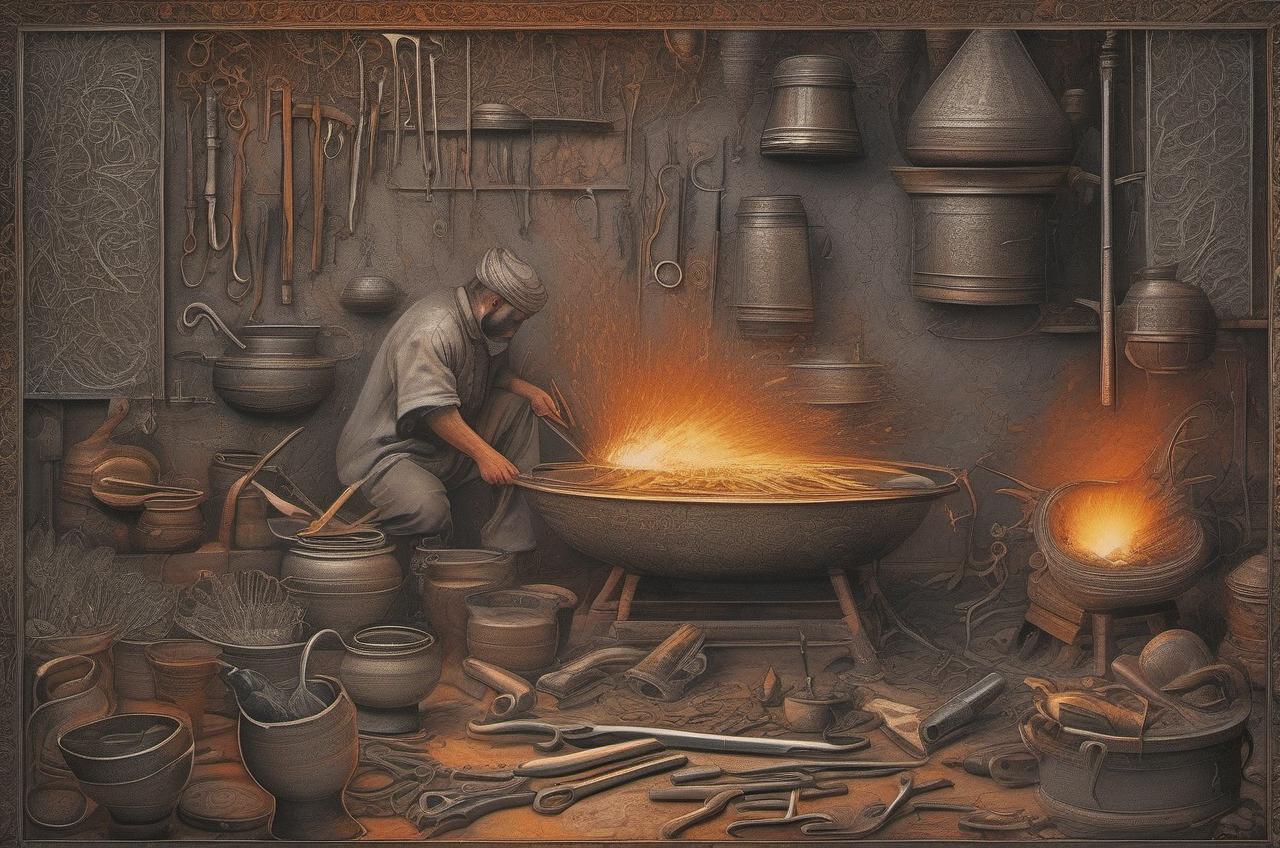

Are you intrigued by the art of metalworking and the exquisite beauty of Damascus steel? This ancient material is renowned for its distinctive patterns and remarkable strength, making it a favorite among craftsmen and collectors alike. Whether you’re a seasoned blacksmith or a curious beginner, understanding how to make Damascus steel can inspire creative projects and deeper appreciation for this fascinating craft.

To make Damascus steel, you start by layering different types of steel or iron, which you then forge weld together at high temperatures. Through a series of hammering, folding, and heat treatments, the metal takes on a unique wavy or patterned appearance. Finally, etching the steel enhances the visual impact, revealing the intricate designs and characteristics that make Damascus steel so appealing.

In this exploration into the world of Damascus steel, we’ll first delve into what exactly it is and why it holds such a revered place in the metalworking community. You’ll learn about its rich history—from ancient civilizations to modern-day techniques—and discover the compelling reasons why artisans continue to create this extraordinary metal. Finally, we’ll discuss the materials and tools you’ll need to embark on your own journey of making Damascus steel.

What is Damascus Steel?

Damascus steel is a type of steel characterized by its distinctive patterns of banding and mottling. It often mimics the swirling patterns of flowing water, which is why many pieces of Damascus steel resemble artistic masterpieces. Initially, the term “Damascus steel” referred to a specific type of steel produced in the Near East, particularly in regions like Syria. However, the definition has evolved, and today it encompasses a variety of modern techniques that yield similar aesthetic qualities.

Damascus steel is renowned not just for its beauty but also for its functional properties. It is incredibly hard and tough, making it ideal for tools and blades. The layered structure gives it superior strength, allowing it to maintain a sharp edge longer than many other types of steel. Blacksmiths appreciate its unique ability to combine hardness with ductility, ensuring that it does not easily chip or shatter.

In addition to its utility, the allure of Damascus steel lies in its artistry. Each piece can be entirely unique, with patterns resulting from how the metal is processed during forging. This variation means that each item made from Damascus steel tells a story, capturing the handwork and craftsmanship of the artisan behind it. Moreover, the tradition of making Damascus steel has been passed down through generations, making every blade or tool infused with history and skill.

The History of Damascus Steel

The origins of Damascus steel can be traced back to ancient India and the Middle East. It was first developed over a thousand years ago when blacksmiths discovered techniques for melting and shaping iron and steel. The remarkable properties of this steel fascinated craftsmen and became a vital component in producing weapons, especially swords. The precise techniques were closely guarded secrets, often shared only within families or guilds.

The name “Damascus” is believed to derive either from the Syrian city where the trade flourished or from the “damask” fabric that featured similar swirled patterns. Over time, various techniques for producing steel were developed, including the method of folding metal, which ultimately enhances both performance and aesthetic appeal. For instance, the incorporation of different materials allows unique patterns to emerge during the forging process.

With the passage of time, the art of making Damascus steel began spreading globally, influencing various cultures’ metalworking styles. In Japan, the tradition of making swords, known as “tamahagane,” utilizes principles similar to those in Damascus steel production. Meanwhile, European blacksmiths adopted and adapted these techniques during the Middle Ages, leading to the flourishing of unique regional styles.

As industry evolved, so too did the methods for producing steel. The rise of modern manufacturing techniques overshadowed artisanal steel-making traditions. However, the allure of handmade Damascus steel has seen a resurgence in recent decades. Craftsmanship has regained popularity, with many artisans dedicated to reviving age-old methods and infusing contemporary designs into their work.

Why Make Damascus Steel?

There are numerous reasons to explore the art of making Damascus steel. First and foremost is the uniqueness that comes with every piece. As no two layers of steel will react in precisely the same way during the forging process, each result is a one-of-a-kind creation. Whether you’re crafting knives, swords, or decorative items, the outcome is always a surprise, embracing the element of chance and creativity.

Another compelling reason to create Damascus steel is its strength and durability. The layered construction not only adds to its aesthetic appeal but also enhances its overall performance. Blades made from Damascus steel boast impressive edge retention and resilience under stress. Therefore, they are highly regarded for functional tools, especially in kitchens and survival scenarios.

Not to forget, making Damascus steel can be incredibly satisfying. Engaging in the crafting process allows you to immerse yourself in a time-honored tradition. The challenges involved in layering, forging, and etching can be immensely rewarding. As you watch the piece transform under your hands, the experience becomes a blend of artistry and skill.

Additionally, working with Damascus steel provides an opportunity to connect with history. By creating something that has roots in ancient civilizations, you’re carrying forward a legacy. Each hammer strike reverberates with stories of craftsmen from centuries past, as you become a part of that lineage.

Finally, the community aspect surrounding Damascus steel cannot be ignored. Engaging with other artisans and enthusiasts can foster friendships and shared knowledge. Whether you attend workshops, join online forums, or participate in local events, the camaraderie enhances your journey into the world of steel craftsmanship.

Materials Needed

Creating Damascus steel requires a few essential materials and tools. Understanding what you need is crucial for a successful forging experience. The most important components are the types of steel used. Traditionally, a combination of high-carbon steel and low-carbon steel is layered together. This contrast in carbon content allows for the unique properties that define Damascus steel. Common choices include 1095 and 15N20 steels. Using these materials creates the best aesthetic and functional qualities.

In addition to steel types, you’ll need some basic tools. The first is a forge. A forge is essential for heating the steel to the required temperatures. You can purchase a pre-made forge or build your own using fire bricks and a burner. Next, you’ll need an anvil. Anvils provide a solid and flat surface for hammering the steel into shape. A good anvil can withstand repeated impacts without warping.

Tools like hammers and tongs are equally important. Hammers come in different sizes and weights, allowing for various shaping techniques. Tongs help you manipulate hot metal safely. It’s also wise to have a dipping bucket filled with water. This is useful for cooling and hardening the steel after shaping.

Safety gear cannot be overlooked. Protective gloves, goggles, and aprons are crucial to safeguard against burns and flying sparks. Working with high temperatures can be hazardous, so ensure you’re well-prepared before starting your project. Investing in quality materials and tools from the beginning will set the stage for a successful Damascus steel-making journey.

Remember, preparation is half the battle. Gather all your materials and tools before you begin. Familiarizing yourself with each of these elements will not only ease the process but also create a smoother workflow as you forge your new masterpiece. Being well-equipped adds enjoyment and satisfaction to your crafting experience.

Steps to Create Damascus Steel

Making Damascus steel involves a careful and methodical process. To start, layer your chosen steels. Depending on the desired pattern, stack alternating layers of high-carbon and low-carbon steel. This will typically involve 3 or more layers, but you can create more complex patterns with additional layers. Once your metals are stacked, tightly bind them using wire or clamps to hold them together. This ensures they won’t separate during the welding process.

Next, heat the entire stack in your forge. You want to reach a temperature of around 2,200 degrees Fahrenheit (1,200 degrees Celsius). The goal is to bring the metals to a glowing orange state. Once the appropriate temperature is achieved, remove the stack from the forge using tongs. Quickly and carefully, place it on the anvil. Use a hammer to forge weld the layers together. Applying even pressure will bond the layers, creating a solid block of Damascus steel.

After welding, it’s time to fold the steel. This involves taking the welded block and folding it over itself, then hammering it flat again. This process can be repeated multiple times, resulting in more layers and intricate patterns. Each fold enhances the visual complexity as it enhances strength and durability. Depending on your desired outcome, consider how many folds you want to make. More folds mean more complex patterns.

Now comes the shaping of the steel. Utilize your hammer and anvil to start forming your blade or desired shape. Pay close attention to the steel’s heat; if it cools down too quickly, return it to the forge. After the rough shape is achieved, it’s time for precision work. Use finer hammers and planishing techniques to refine the blade until it meets your standards.

After finishing the shaping, it is crucial to heat treat the steel. Heat the blade to a specific temperature, then quench it in oil or water. This hardens the steel and sets the structural integrity. The next step is tempering. This involves heating the steel again at a lower temperature to relieve stress and improve toughness. Once these steps are completed, your Damascus steel should be ready for the final touch—etching.

Tips for a Successful Result

Producing high-quality Damascus steel can be challenging. However, with some attention to detail, you can make it a rewarding experience. One key tip is to manage your heat well. Proper temperature control is vital throughout the process. If the steel is too cold, it won’t weld properly. Conversely, overheating can ruin the piece. Use a pyrometer or thermocouple to monitor temperatures accurately.

Another tip is to take your time. Rushing through the forging process can lead to mistakes. Each stage requires focus and precision. Make sure to give yourself the space and time needed to ensure quality results. If you find yourself losing focus, take a step back and breathe. Maintaining a calm mindset will contribute to better outcomes.

Additionally, always experiment with different patterns. One of the most exciting aspects of making Damascus steel lies in its variability. Playing with the arrangements, number of layers, or even the steel types can lead to unique designs. Keep in mind that mistakes can lead to unexpected beauty. Don’t hesitate to embrace the art in serendipity.

Documentation can be beneficial, too. Keep track of your methods and materials used for each piece. Noting down temperatures, times, and processes will serve as a guiding reference for future projects. Plus, you’ll enjoy reflecting on your progress and growth as a craftsman!

Lastly, remember to stay safe. Always use proper safety equipment while working with high heat and sharp tools. Working safe ensures that you will continue this craft for years to come. A dangerous workspace can lead to accidents, dampening the joy of creation. Make safety a priority, and enjoy the rewarding process of crafting your own Damascus steel.

Uses of Damascus Steel

Damascus steel is cherished across various fields for its unique properties and stunning aesthetics. One of the most prominent uses is in crafting knives. Chefs and outdoor enthusiasts alike appreciate the sharpness and edge retention that comes with Damascus steel blades. The combination of high and low carbon content allows for superior performance when cutting through ingredients or preparing meals.

In addition to kitchen knives, swords made from Damascus steel hold a legendary status. Throughout history, warriors revered these weapons for their durability and ability to hold a sharp edge. Even today, many swordsmiths use traditional techniques to forge Damascus steel blades, marrying history with modern craftsmanship. Collectors and martial artists often seek these swords for both performance and aesthetic value.

Jewelry is another fascinating application of Damascus steel. Artisans craft rings, pendants, and bracelets that showcase the stunning patterns unique to this material. The intricate designs add sophistication and uniqueness to each piece. Wearing Damascus steel jewelry becomes a way to express personal style while appreciating the artistry behind its creation.

Furthermore, decorative art pieces can be made from Damascus steel. Artists and blacksmiths create sculptures, wall hangings, and other ornamental items that showcase the beautiful patterns. These pieces often become conversation starters, attracting attention for their exquisite detail. Using Damascus steel for décor allows hobbyists and professionals to explore their creativity while celebrating a time-honored craft.

Lastly, Damascus steel finds its way into hand-tools. Blacksmiths, woodworkers, and craftsmen utilize the material for chisels, hammers, and other implements. These tools benefit from the strength and durability of Damascus steel, providing reliable performance over time. The beauty of the material adds a unique touch to functional items, making them as enjoyable to use as they are to behold.

Maintaining and Caring for Damascus Steel

To keep your Damascus steel items looking stunning and performing well, proper care is essential. Cleaning is a critical first step. After each use, gently wipe down your blades with a soft cloth. Avoid using abrasive materials that can scratch the surface and ruin the beautiful patterns. For knives, it’s best to wash them with warm water and mild soap, then dry thoroughly to prevent rust.

Preventing rust is another important consideration. While Damascus steel is often more resistant to corrosion than standard steel, it still requires attention to keep it in top condition. Always dry your blades immediately after washing. Store them in a dry place, preferably in a sheath or on a magnetic strip that keeps them protected. If your knife has a particularly intricate design, consider applying a light coat of mineral oil to the surface for extra protection.

Another aspect of maintenance is sharpening. Regularly honing your Damascus steel knives will keep them performing at their best. Use a high-quality whetstone or honing rod to maintain the edge. Be mindful when sharpening to maintain the angle of the blade. With proper technique, you can keep your knives sharp for years to come.

If you own decorative or collectible items made from Damascus steel, take care when displaying them. Avoid exposure to moisture and direct sunlight, as these conditions can degrade the material over time. If your item gathers dust, use a soft, dry cloth to gently remove it without risking damage to the surface.

Lastly, remember that while Damascus steel is hardy, it still benefits from occasional professional care. If you notice any significant damage or wear, consult with a professional blacksmith or bladesmith to restore it to its former glory. Regular professional maintenance ensures that your Damascus steel items remain beautiful and functional for generations.

FAQs

What makes Damascus steel unique?

Damascus steel is unique due to its distinctive patterns created by layering different types of steel and iron. The technique gives each piece a one-of-a-kind look while also enhancing its functional properties, such as strength and edge retention. The swirling patterns not only serve an aesthetic purpose but also indicate the skill and craftsmanship that went into making the steel.

How do I clean Damascus steel knives?

To clean Damascus steel knives, rinse them with warm water and mild soap after each use. Avoid using abrasive scrubbers, as they can scratch the surface and damage the intricate patterns. After washing, dry the knife immediately to prevent rust, and consider applying a light coat of mineral oil for added protection during storage.

Can I use dishwasher for Damascus steel cutlery?

No, it is not recommended to use a dishwasher for Damascus steel cutlery. The harsh environment, including high temperatures and detergents, can damage the blade and lead to corrosion. Hand washing and drying are always the best practices to ensure the longevity of your Damascus steel items.

Is it safe to sharpen Damascus steel?

Yes, it is safe to sharpen Damascus steel knives, but it should be done carefully. Use a high-quality whetstone or honing rod, and maintain the original angle of the blade while sharpening. Regular honing will keep the edge sharp without damaging the beautiful surface patterns.

What types of projects can I make using Damascus steel?

You can create a variety of projects using Damascus steel, including kitchen knives, swords, jewelry, and decorative art pieces. Additionally, many craftsmen use Damascus steel to make hand tools like chisels and hammers, as the material offers both beauty and durability across various applications.

How can I tell if my Damascus steel is of high quality?

High-quality Damascus steel will exhibit clear, intricate patterns and a smooth finish. It should feel solid and balanced when held. Also, check for signs of poor welding, such as gaps between layers or significant blemishes. A reputable maker will usually provide information on the materials used and the techniques employed in creating the steel.