Aluminum wiring has a fascinating history that intertwines innovation and safety. Once hailed as a lightweight and cost-effective alternative to copper, aluminum wiring quickly made its mark in homes and businesses across the United States. However, as time went on, the widespread use of aluminum wiring also revealed serious concerns about electrical safety. In this post, we will explore the timeline and implications of aluminum wiring, answering the essential question: when was aluminum wiring banned?

Aluminum wiring was never outright banned; however, its use was significantly restricted starting in the early 1970s due to safety concerns. The National Electrical Code (NEC) made key changes during this period, advising against the use of aluminum wiring for residential purposes. Moreover, the Consumer Product Safety Commission highlighted the dangers associated with aluminum wiring, leading to stricter regulations and recommendations for existing homes.

Throughout this discussion, we will delve deeper into the history of aluminum wiring, starting with its initial popularity during the 1960s and 1970s. We will examine its common applications, which made it a go-to choice for builders and electricians of that era. As we continue, we will highlight the issues and concerns that arose, sparking a national conversation about safety.

Next, we will cover the birth of the aluminum wiring controversy, discussing pivotal incidents that caused public alarm. We’ll then explore the regulatory changes implemented over the years, particularly the timeline of significant actions by the NEC to address safety concerns. Moreover, we will break down the current standards surrounding wiring materials and what has changed in today’s building codes.

Finally, we’ll address the implications of these regulations on homeowners and the real estate market, and what homeowners should know if they have aluminum wiring still in their properties. We’ll even provide insights into alternatives to aluminum wiring, guiding you through modern electrical options that prioritize safety and efficiency.

What is Aluminum Wiring?

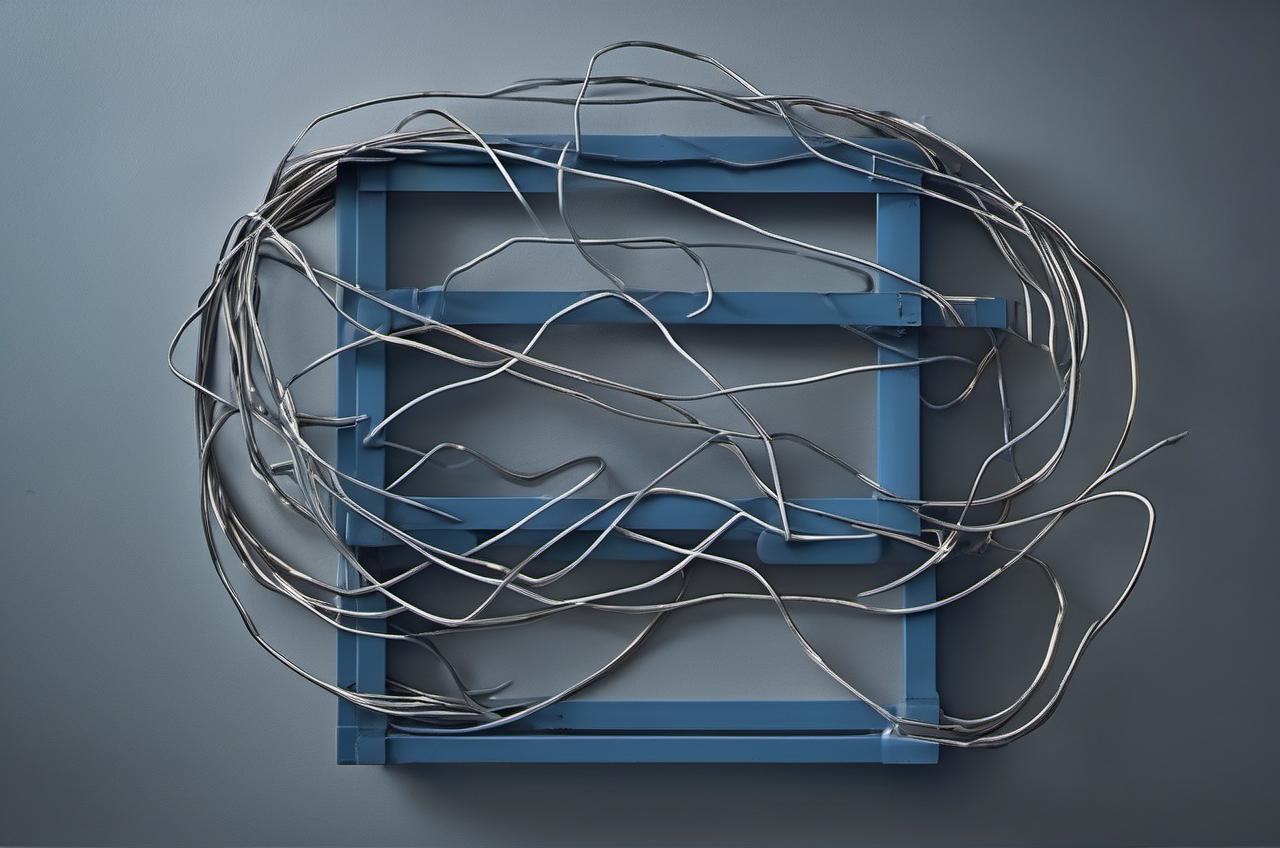

Aluminum wiring is a type of electrical wiring made from aluminum rather than copper. It gained popularity due to its lightweight nature and lower cost, making it an attractive option for residential and commercial builders alike. This type of wiring was often used in new housing developments during the 1960s and 1970s, a time when the demand for affordable housing skyrocketed. Builders aimed to reduce material costs while still ensuring adequate electrical service, and aluminum promised an effective solution.

Aluminum is a malleable and conductive material, meaning it can carry electricity effectively compared to other materials. One of the key advantages was cost—aluminum wiring was significantly cheaper than copper. The construction industry saw this as a win-win situation; reduced material costs would lower overall expenses without compromising quality. However, this seemingly perfect solution came with hidden drawbacks that would later surface.

The Rise of Aluminum Wiring in the 1960s and 1970s

During the 1960s and 1970s, aluminum wiring became a go-to choice for new construction projects. The housing boom during this period created a need for cost-effective materials that could keep up with demand. Construction companies turned to aluminum because it was not just cheaper but also lighter than copper, simplifying the installation process.

The expansion of suburban housing developments across the U.S. showcased aluminum wiring’s widespread use. Many homes constructed during this time featured aluminum wiring in their electrical systems, which provided sufficient power to meet the rising demands of household appliances. This included everything from electric stoves to air conditioning units, making aluminum integral to modern American life.

Despite its growing popularity, the long-term implications of aluminum wiring began to surface. Issues regarding its connection with safety risks began to emerge as homes with aluminum wiring aged. Homeowners were often unaware of these potential dangers, leading to bigger concerns as the years passed.

Issues and Concerns with Aluminum Wiring

As aluminum wiring gained traction, it became increasingly apparent that it was not without its flaws. One of the primary concerns was its tendency to expand and contract with temperature changes. This characteristic, combined with improper installation techniques, led to loose connections that could cause electrical arcing— a situation that poses serious fire hazards.

Electrical arcing occurs when electricity jumps from one conductor to another, which can ignite surrounding materials. This issue was exacerbated if the aluminum wiring was not properly installed or if installers used the wrong connectors. As time went on, the combination of these factors resulted in numerous reported incidents of electrical fires, raising alarms among homeowners and safety officials alike.

Statistical data concerning incidents involving aluminum wiring indicated a worrisome trend. Reports outlined that homes with aluminum wiring were at a significantly higher risk of electrical failures compared to their copper counterparts. In some cases, the electrical issues led to injuries and property damage, further emphasizing the importance of addressing this growing concern.

Homeowners began to educate themselves about the risks associated with aluminum wiring, and alarmed parents and homeowners unions called for more stringent regulations to protect families and their properties. This awareness played a crucial role in shifting public opinion, leading to more scrutiny on aluminum wiring.

As concerns heightened, so did the pressure on regulatory bodies to act. The following sections will explore how various agencies and standards organizations responded to these growing issues and what regulations emerged in response.

The Birth of the Aluminum Wiring Controversy

The controversy surrounding aluminum wiring began to take shape in the late 1970s. As fires caused by faulty aluminum wiring gained media attention, public concern surged. Homeowners were left feeling uneasy about the safety of their homes. This anxiety grew in tandem with reports of electrical fires linked to aluminum wiring installations.

One of the most notorious incidents occurred in the early 1970s when a fire in a Los Angeles home prompted investigations. Fire safety officials discovered that aluminum wiring was a significant factor in the blaze. Residents of the neighborhood were shocked. Many had no idea that the wiring in their homes posed such a threat.

These alarming stories spread quickly. Articles began appearing in newspapers nationwide, highlighting the risks associated with aluminum wiring. Investigations by local fire departments revealed that these incidents were not isolated. Homeowners started checking their wiring, fearing they too might be at risk. The situation reached a point where organizations like the Consumer Product Safety Commission (CPSC) began to take a serious look at the issue.

Consumer advocacy groups joined the fray, demanding stricter regulations. They aimed not just to inform the public but to hold builders and manufacturers accountable for the materials used in construction. Public awareness campaigns intensified, pushing for action on a national level. Plus, safety organizations and electrical contractors urged homeowners with aluminum wiring to take precautions or consider replacements.

The result was a gathering storm of public pressure that would drive regulators to respond. The fear surrounding aluminum wiring evolved into a broader conversation about electrical safety. It became undeniable that something needed to be done. The stage was set for subsequent regulatory actions and industry changes.

When Were Regulations Implemented?

The first major regulatory response occurred in 1972, when the National Electrical Code (NEC) made significant changes. Those revisions aimed to address the growing concerns surrounding aluminum wiring. The NEC recommended using copper wiring instead, particularly in residential installations. They noted that aluminum was more prone to problems like overheating and fire risks.

As the years progressed, more specific guidelines were implemented. In 1975, the NEC introduced stricter standards for aluminum wiring, focusing on installation and connection practices. Electricians were required to use specific connectors rated for aluminum wiring. This meant that not just any connector would do; they had to ensure proper compatibility.

Throughout the late 1970s, the regulatory landscape continued to evolve. By 1978, the CPSC published information that detailed the hazards linked to aluminum wiring. Their findings provided a clearer understanding of the risks and offered recommendations for homeowners. The CPSC suggested various approaches, such as upgrading to copper wiring or using specialized connectors and fittings that could mitigate some of the risks associated with aluminum.

The presence of these guidelines and recommendations significantly impacted the construction industry. Builders began to reconsider their choices, especially for new residential projects. While new constructions using aluminum wiring were still allowed, builders increasingly opted for copper materials. Additionally, existing homeowners were encouraged to have their electrical systems evaluated. Those with aluminum wiring were often advised to perform upgrades or replacements.

As a result of these ongoing changes in regulations and growing awareness, the installation of aluminum wiring in new homes retreated significantly in the following decades. The NEC’s updates and the CPSC’s recommendations clearly shifted the industry’s perspective on wiring materials. The call for increased safety and responsiveness to consumer concerns ultimately reshaped how electrical systems were designed and installed across the country.

Understanding the Current Codes and Standards

Today, the standards surrounding electrical wiring materials are stricter than ever. The National Electrical Code (NEC) continuously updates its guidelines to enhance the safety of wiring installations. As a homeowner, it’s essential to be aware of how these codes affect your home. The current codes don’t outright ban aluminum wiring; however, they do impose specific restrictions and requirements to ensure safety.

For instance, if aluminum wiring is used, it must be connected with appliances and devices that are approved for use with aluminum. This requirement helps prevent the overheating and fire hazards that existed in homes built during the 1960s and 1970s. It’s crucial for electricians to utilize connectors and junction boxes specifically designed for aluminum wiring. Homeowners should ensure that any electrical work is performed by licensed professionals aware of these regulations.

Moreover, the NEC emphasizes the importance of proper installation techniques. For example, when making connections or splicing aluminum wiring, specific procedures must be followed to ensure safety and compliance. If any upgrades or repairs need to happen in homes with aluminum wiring, having a qualified electrician perform the work is critical. Doing so guarantees adherence to current codes and minimizes risks.

In recent years, there has been a growing movement toward increased transparency in construction materials. Homebuyers today are encouraged to request documentation regarding the types of wiring installed in homes they are considering. Many real estate transactions now include disclosures about wiring and other electrical systems. This shift in mindset has helped raise awareness and promote safety in electrical installations.

Overall, while aluminum wiring is not outright banned, regulatory changes have significantly reshaped its use and installation in both new and existing homes. Today’s codes prioritize safety above all, ensuring that any wiring—whether aluminum or copper—meets stringent performance standards. Adhering to these current codes and guidelines can ultimately protect homeowners from electrical hazards.

Impact on Homeowners and Real Estate

The changes in regulations regarding aluminum wiring have had a profound impact on homeowners. For many, simply knowing the type of wiring in their homes is essential. Homeowners with aluminum wiring need to be proactive about ensuring their home’s safety. This often includes hiring professional electricians for inspections and, if necessary, upgrades.

Moreover, the presence of aluminum wiring can significantly affect a home’s resale value. Prospective buyers often view homes with aluminum wiring as high-risk, leading to increased scrutiny during home inspections. If the wiring isn’t addressed, it could impact the closing of a sale. Many buyers choose to walk away from homes that may require costly upgrades.

In some cases, a homeowner may opt to make the necessary repairs or electrical upgrades before listing their property. These investments can result in a higher sales price and a faster sale. However, the cost associated with upgrading aluminum wiring can be burdensome. Homeowners need to weigh the expense of replacement against the potential return on investment.

Additionally, some mortgage lenders have started to include wiring assessments as part of their loan approval process. They may require buyers to secure a home inspection that evaluates the condition of the wiring. If aluminum wiring is found, lenders might request an remediation plan before approving financing. This requirement can introduce further complications and delays in the buying process.

Overall, the implications of having aluminum wiring are far-reaching for homeowners and the real estate market. The need for vigilance and due diligence has never been more critical. Understanding how electrical safety regulations impact property value is equally important for both sellers and buyers in today’s market. This growing awareness ensures that homeowners can make informed decisions regarding the safety and value of their properties.

Alternatives to Aluminum Wiring

As concerns about the safety of aluminum wiring have grown, many homeowners are now considering alternative options. The most prevalent alternative is copper wiring. Copper has long been recognized for its superior conductivity and durability. It’s often deemed the gold standard in wiring materials today.

Copper wiring has a number of advantages. For starters, it does not have the same expansion and contraction issues as aluminum. This means that copper wires are less prone to loosening connections and overheating. Moreover, copper is more resistant to oxidation and corrosion, which can lead to failures in aluminum wiring systems. These characteristics make copper an attractive option for both new and existing homes.

For homeowners considering upgrades, the initial cost of copper wiring may be higher, but many view it as a worthwhile investment. Copper wiring systems tend to offer superior performance over time, reducing the likelihood of electrical issues. This means that, although the initial expense may be higher, the long-term savings on maintenance and repairs can justify the investment.

However, there are also innovative alternatives emerging in the market. For instance, some manufacturers now produce composite wires, which combine the strengths of both copper and aluminum. These modern materials aim to provide the benefits of lightweight and cost-effective wiring without many of the risks associated with traditional aluminum wiring.

Additionally, advancements in innovations mean that safety features integrated into modern wiring systems have improved drastically over the years. New connectors designed for aluminum wiring, as well as policies encouraging regular inspections, contribute to a safer overall environment. Homeowners are encouraged to consult licensed electricians about the latest options tailored to their specific needs.

In summary, the rise of safety awareness regarding aluminum wiring has led to a shift in the market towards copper wiring and other innovative alternatives. Both homeowners and builders now have more options than ever before in achieving safe, efficient electrical installations. Exploring these alternatives can provide peace of mind and ensure compliance with the latest safety standards.

Summary of the Aluminum Wiring Ban and Its Significance

The conversation around aluminum wiring has evolved considerably since its early adoption in the 1960s and 1970s. Initially seen as a cost-effective solution, concerns about its safety led to significant changes in regulations. While aluminum wiring was never outright banned, its use has been heavily restricted due to the inherent dangers it poses. The implementation of guidelines from organizations such as the National Electrical Code (NEC) highlights the need for safety in electrical systems.

Understanding these regulations is essential for homeowners today. The information about aluminum wiring and its associated risks continues to play a critical role in ensuring electrical safety. Homeowners who may have inherited aluminum wire or are considering purchasing such a property need to be vigilant. Regular inspections and understanding potential hazards should be part of their due diligence.

Another significant factor is its impact on the real estate market. Homes with aluminum wiring may face challenges during the selling process. Potential buyers are often wary of the risks associated with aluminum wiring, which can lead to delayed sales or negotiations for lower prices. The changes in perception can sometimes make selling a home with aluminum wiring a tough sell, reinforcing the importance of addressing electrical systems preemptively.

Additionally, the recommendations from the Consumer Product Safety Commission (CPSC) have been crucial. They pushed for awareness of the risks and encouraged homeowners to consider upgrades to safer wiring materials. This momentum helps facilitate conversations around electrical safety and drives homeowners to make informed choices, thus ensuring their families’ safety.

Overall, while the use of aluminum wiring persists in some homes, the regulations and public awareness have led to a significant shift in how we view electrical safety. Understanding the history and implications of aluminum wiring allows homeowners to make informed choices about their electrical systems and protect themselves from potential hazards.

Tips for Homeowners with Aluminum Wiring

If you have aluminum wiring in your home, there are several important steps you should take to ensure safety. First and foremost, it’s vital to have your wiring inspected by a licensed electrician. They can evaluate the condition of the wiring, identify potential risks, and suggest necessary actions. This inspection will give you a clearer understanding of your home’s electrical system.

In addition to inspections, consider upgrading your aluminum wiring to copper. While this may require higher initial costs, the long-term benefits often outweigh the expenses. Copper wiring is known for its durability and significantly lower risk of fires or electrical issues. An electrician can help establish a plan for replacing existing wiring, ensuring compliance with electrical codes.

Moreover, if you decide to keep your aluminum wiring, ensure that all connectors and devices are suitable for aluminum use. Special connectors are designed to minimize the risk of overheating and electrical failure. This precaution can help you avoid many of the common issues associated with aluminum wiring.

Education is another key aspect for homeowners. Being informed about the specific risks associated with aluminum wiring can empower you to take appropriate precautions. Learn about proper care and maintenance and understand the importance of monitoring your electrical system regularly. This awareness will help you identify any signs of trouble early on.

Lastly, consider keeping documentation of any electrical work done on your home. This record can come in handy when dealing with potential buyers or insurance companies. It adds value to your home and provides reassurance to prospective buyers regarding the upkeep of your electrical systems.

Taking proactive measures can greatly reduce risks associated with aluminum wiring. Dedication to safety not only protects your family but also enhances the longevity and value of your property.

The Role of Electricians in Managing Aluminum Wiring

Licensed electricians play a crucial role in managing aluminum wiring in homes. Their expertise is invaluable when it comes to ensuring safety and compliance with current regulations. An electrician is skilled in identifying potential hazards associated with aluminum wiring and can provide essential services, including inspections, repairs, and installations.

When you hire an electrician, they will first assess the existing wiring and the overall condition of your electrical system. They can identify any loose connections or signs of wear and tear that might pose a risk. Many homeowners may overlook these small details, but electricians are trained to spot even minor inconsistencies that could develop into more significant issues.

Additionally, electricians can guide homeowners on the best practices for maintaining aluminum wiring. They know which connectors are appropriate for aluminum and can ensure that all installations comply with safety codes. Hiring a qualified electrician to perform regular maintenance and inspections can help prevent electrical failures or hazards like fires.

If a homeowner decides to replace aluminum wiring with copper, an electrician can facilitate a seamless transition. They are equipped to reroute new wiring, ensuring energy efficiency while maintaining the home’s design integrity. This process is crucial in maintaining safety standards.

Moreover, an electrician can also address any concerns about compatibility between new appliances and existing wiring systems. Many modern appliances require specific types of wiring to function effectively. An electrician will ensure that your home meets these requirements, allowing you to use the latest technology without concerns.

In summary, the expertise of licensed electricians is essential when addressing aluminum wiring issues. From assessments to repairs and installations, their knowledge ensures that homeowners can make informed decisions. Partnering with an electrician ultimately enhances the safety and efficiency of a home’s electrical system.

Future Trends in Electrical Wiring

As technology advances and awareness of electrical safety grows, trends in wiring materials are evolving too. The focus on using safer, more efficient materials is paving the way for innovations in electrical wiring. With a push toward renewable energy, the demand for wires that can handle increased loads is also rising.

One of the most significant trends is the increased use of smart wiring systems. These systems offer real-time monitoring of energy usage, alerting homeowners to potential issues before they escalate. Smart wiring improves energy efficiency and places safety at the forefront of modern design. Homeowners can adjust their usage patterns, saving money while prioritizing safety.

Moreover, advancements in materials science are introducing new wiring solutions designed to mitigate the risks associated with traditional aluminum wiring. Innovations like composite wiring, which combines the benefits of aluminum and copper, are being developed. These materials aim to retain cost advantages while reducing fire hazards and improving longevity.

Sustainability is another trend influencing electrical wiring choices. As demand for green building materials grows, many construction companies are seeking eco-friendly wiring options. Biodegradable or recycled materials are becoming more commonplace, allowing homeowners to reduce their energy footprint while maintaining safety and efficiency.

Lastly, public awareness will continue to drive changes in regulations and standards. Educational campaigns about the risks associated with wiring materials will keep homeowners informed and proactive. This increased vigilance creates demand for further innovation, leading to even safer and more efficient wiring solutions.

In summary, the future of electrical wiring is promising. Innovations aimed at improving safety and efficiency are constantly emerging. Homeowners can look forward to a wide range of choices that prioritize sustainability and meeting the demands of a technology-driven world. Staying informed about these trends will empower homeowners to make the best decisions for their families and properties.

FAQs

When was aluminum wiring first used in homes?

Aluminum wiring was first widely used in homes during the 1960s and 1970s. It gained popularity as a cost-effective alternative to copper, particularly during a time when there was a housing boom and an increasing demand for affordable construction materials.

Is aluminum wiring still allowed in homes today?

Yes, aluminum wiring is still allowed in homes today, but it is subject to strict regulations. Local building codes and the National Electrical Code (NEC) provide guidelines on the safe installation and use of aluminum wiring. Although it can be used, homeowners with aluminum wiring are often advised to have their systems inspected and consider upgrades to safer alternatives.

What are the main risks associated with aluminum wiring?

The main risks of aluminum wiring include overheating, loose connections, and electrical arcing, all of which can lead to fire hazards. Over time, aluminum wires can expand and contract with temperature changes, causing connections to loosen, which increases the chance of arcing and potential fires.

How can homeowners ensure their aluminum wiring is safe?

Homeowners can ensure their aluminum wiring is safe by having it inspected by a licensed electrician. Regular inspections allow for the identification of any loose connections or wear and tear, which can lead to issues. Additionally, using connectors designed specifically for aluminum wiring can help mitigate risks.

What should I do if I have aluminum wiring in my home?

If you have aluminum wiring in your home, it is best to schedule an inspection with a qualified electrician. They can assess the condition of your wiring and provide options for upgrades or repairs. It’s also wise to educate yourself on the unique maintenance needs and risks associated with aluminum wiring to stay proactive about safety.

Are there any alternatives to aluminum wiring?

Yes, the most common alternative to aluminum wiring is copper wiring. Copper is known for its superior conductivity, durability, and lower risk of fire hazards. Additionally, newer materials like composite wiring, which combines the benefits of both aluminum and copper, are being developed to enhance safety and efficiency in electrical systems.