Extruded aluminum is a popular material among builders, DIY enthusiasts, and manufacturers alike. Its lightweight nature and strength make it perfect for a variety of applications. Whether you’re constructing a frame, crafting furniture, or creating custom projects, knowing how to cut extruded aluminum properly can be a game changer. Let’s dive into the essentials of this versatile material and how you can make clean, precise cuts.

Cutting extruded aluminum requires the right tools and techniques. Using a suitable saw and following best practices will help you achieve clean cuts without causing damage to the material. Depending on the type and thickness of the aluminum, you can select from various cutting methods to ensure efficiency and precision.

To set the stage, this piece will cover the fundamentals of extruded aluminum, highlighting its benefits and various types available in the market. We’ll then discuss the tools you’ll need for cutting, safety precautions to keep in mind, and how to prepare your workspace effectively. Finally, we’ll delve into various cutting techniques with detailed guidance for each tool, including tips for achieving the best results possible.

What is Extruded Aluminum?

Extruded aluminum is a process where aluminum is transformed into a specific shape by forcing it through a die. This technique allows for the creation of complex shapes and forms that can be tailored for numerous applications, from structural components to aesthetic designs. The extrusion process is not just functional; it also enables manufacturers to produce lightweight yet durable products that are easy to handle.

The versatility of extruded aluminum makes it suitable for numerous industries. You’ll find it commonly used in architecture for window frames and curtain walls, in machinery for structural supports, and even in household items like furniture. Its adaptability allows designers to create customized components that meet specific project requirements. Overall, extruded aluminum blends functionality with aesthetic appeal beautifully.

Benefits of Using Extruded Aluminum

One of the most significant advantages of extruded aluminum is its lightweight nature. This property makes it easier to transport and handle than many other materials, reducing shipping costs and installation time. Whether you’re moving materials on-site or working on delicate projects, the lower weight makes a tangible difference.

Another key benefit is its corrosion-resistant properties. Aluminum naturally forms a protective oxide layer when exposed to air, which prevents rust and decay. This characteristic makes extruded aluminum an excellent choice for outdoor applications or environments that may be exposed to moisture. By choosing aluminum, you ensure that your structures will stand the test of time without the need for frequent maintenance.

Additionally, extruded aluminum is incredibly versatile when it comes to design. Its ability to be shaped into intricate profiles allows creative freedom for designers. Coupled with its ease of finishing, it can be painted or anodized to suit a variety of aesthetics. This adaptability makes it a favorite among architects and artists alike.

Lastly, while durable, aluminum is also recyclable, making it an environmentally friendly choice. Recycled aluminum requires significantly less energy to produce than new aluminum, reducing your carbon footprint in the process. The ability to repurpose this material aligns perfectly with sustainable building practices, offering a double benefit: a robust product and a reduced impact on the environment.

Different Types of Extruded Aluminum Profiles

Extruded aluminum comes in a variety of shapes and profiles, each designed for specific functions. Understanding these profiles is crucial for selecting the right one for your project. Commonly used profiles include T-slots, angles, channels, and tubes, each with unique designs and applications.

T-slots are frequently used in framing systems and assembly projects. Their distinctive shape allows for easy connection and adjustment of components, making them perfect for modular setups. Users can incorporate various attachments and accessories with T-slots, providing flexibility in design and construction.

Angles, on the other hand, are fundamental in structural applications. Their L-shaped design provides excellent support and stability, making them ideal for creating frames or supports. They can be used in both horizontal and vertical configurations, depending on project requirements, allowing for straightforward assembly of larger structures.

Channels serve as a robust solution for guiding, installing, and supporting other materials. They are often used in the construction of shelves, brackets, and other load-bearing applications. These profiles provide a sense of direction and structure to your projects while remaining lightweight and resistant to environmental factors.

Tubing is another popular shape in extruded aluminum. Commonly seen in furniture design, bicycle frames, and construction, aluminum tubing combines a sleek appearance with excellent strength-to-weight ratios. Users have the freedom to choose from different diameters and wall thicknesses, allowing for customization based on specific use cases and load requirements.

Recognizing the distinct properties of these profiles helps you select the proper aluminum for your project. It ensures you get the right material for functionality, aesthetics, and durability. Understanding your options can make the difference between a successful outcome and a haphazard approach to construction or assembly.

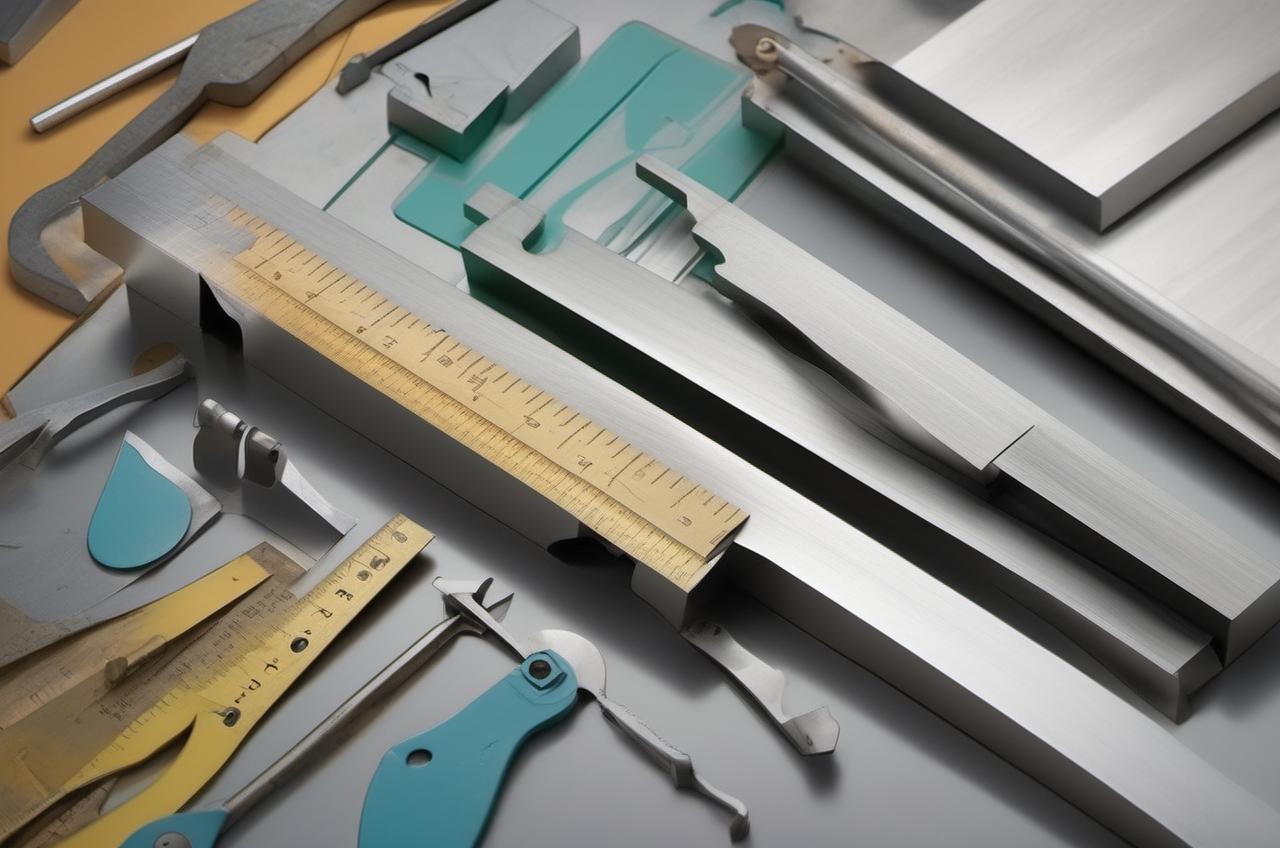

Essential Tools for Cutting Extruded Aluminum

To cut extruded aluminum effectively, you need the right tools. Each tool has its strengths, and choosing the correct one depends on your project needs. Here are some essential tools for cutting aluminum, along with their features.

Hacksaws are a popular choice for small projects. They are lightweight and easy to handle, making them perfect for intricate cuts. When using a hacksaw, aim for a blade with finer teeth. This ensures cleaner cuts and reduces the chance of deformation. While they require more effort, hacksaws offer great control, especially when working on detailed designs.

A miter saw is ideal for making precise angled cuts. Its ability to adjust angles allows for versatility in cuts, making it a go-to for framing tasks. When using a miter saw, ensure you use a carbide-tipped blade designed for cutting non-ferrous metals like aluminum. This will provide a smooth, clean cut while minimizing wear on the blade and material. The ease of operation also means you can cut multiple pieces quickly.

For larger projects, a band saw provides significant advantages. Band saws can handle thick aluminum with ease and offer adjustable speed settings. This flexibility helps protect the material, preventing overheating during cutting. Additionally, band saws produce minimal waste, allowing for more efficient usage of your aluminum. They are a great investment for anyone regularly working with this material.

Table saws are versatile tools that offer precision and speed. They allow for long, straight cuts and are perfect for various thicknesses of aluminum. You need to ensure you have the appropriate blade and setup to prevent kickback, which can happen if not handled properly. When using a table saw, pay attention to the feed rate and pressure applied to the material. This control can make all the difference.

Lastly, hand shears are an excellent tool for quick cuts on thinner aluminum sheets. They work similarly to scissors and are very user-friendly. Hand shears are perfect for small projects or finishing touches where precision isn’t the top priority. However, when opting for hand shears, ensure that the material is flat and secure to get the best results.

Equipping yourself with the right tools can elevate your cutting game. Choosing the appropriate instrument based on the thickness and size of the aluminum will play a significant role in achieving clean cuts and avoiding unnecessary complications.

Safety Precautions When Cutting Aluminum

Cutting aluminum can lead to hazards if not approached with caution. Even though it’s a relatively manageable material, proper safety measures are essential. Always prioritize safety before you start on any cutting project.

First, make sure you wear appropriate protective gear. This includes safety goggles to protect your eyes from metal shavings or flying debris. A dust mask can also help minimize the inhalation of aluminum dust and particles. Additionally, gloves are also recommended, but choose a type that provides grip while allowing dexterity. This combination forms a basic line of defense against common accidents during cutting.

Next, ensure your work area is well-lit and organized. Clutter can lead to accidents, so keep tools and materials at a safe distance from your cutting area. A clean surface also enhances accuracy while cutting. Moreover, consider wearing steel-toed boots if you are handling heavy pieces of aluminum. This extra layer of protection can mitigate accidents if something falls or slips.

When operating any cutting tool, maintain control and focus. Avoid distractions to keep your mind on the task at hand. Make sure your equipment is in good working order before you start. Regular maintenance and inspection of your tools can prevent mechanical failures and reduce the risk of injury.

Another essential aspect of safety involves securing your aluminum pieces. Always clamp down the material firmly before cutting. This prevents movement that may lead to uneven cuts or, worse, slip-ups that can injure you. If you’re using power tools, keep an eye on the blade alignment. Misalignment can cause the blade to jam or even kickback, which is dangerous.

Finally, be cautious with the edges of the cut aluminum. After cutting, sharp edges can be hazardous. Filing down or sanding these edges can help ensure they are safe to handle. Taking these extra steps will contribute to a safer environment and a more enjoyable cutting experience.

Preparing Your Work Area

Creating a well-organized work area is critical for cutting extruded aluminum effectively. A suitable environment contributes to both safety and efficiency. Start by selecting an appropriate outdoor or spacious indoor location where you can work.

Ensure that your workbench or cutting table is sturdy and stable. The surface should be able to hold the weight of the aluminum profile without wobbling. If you don’t have a designated workbench, consider using sawhorses or even a large piece of plywood. Whichever surface you choose, it should be clean and flat to avoid any disruptions while cutting.

Next, gather all essential tools before beginning. Keeping them within arm’s reach will save you time and make the process smoother. Lay out everything you need: clamps for securing the aluminum, saws, measuring tools, and protective gear. Doing so creates a workflow that allows you to concentrate on making accurate cuts rather than searching for tools mid-project.

Proper lighting is crucial. Ensure your workspace is well-lit to increase visibility when making precise measurements or cuts. If you’re working outdoors, choose a time of day when sunlight is directly on your workspace. For indoor projects, investing in bright overhead or task lighting can significantly improve safety and accuracy.

Another vital aspect of preparation is ensuring adequate ventilation. Cutting aluminum can generate fine particles that may be harmful if inhaled. If possible, work in an area with good airflow, or use a vacuum to clean up dust regularly. If you’re working indoors, consider windows or an exhaust fan to keep the air fresh and breathable.

Finally, don’t forget about personal organization. Keeping a clean and clutter-free workspace minimizes distractions. Just a little tidiness can prevent accidents and improve overall efficiency while cutting your aluminum pieces.

Step-by-Step Guide to Cutting with Each Tool

Hacksaw

Using a hacksaw to cut extruded aluminum is a straightforward process. First, select a blade suitable for metal cutting. The proper teeth count will prevent the blade from binding and will aid in achieving a cleaner cut. Once the blade is chosen, measure the length you need and mark it on the aluminum using a pencil or a marker.

Next, secure the aluminum in a vise or with clamps to prevent movement. This step is critical, as a wobbly piece can lead to inaccurate cuts. Hold the hacksaw with a firm grip and start sawing slowly. Let the blade do the work; pressing too hard can cause the blade to overheat or break. Maintain steady, even pressure, and remember to refresh your grip as you saw through the material.

Keep an eye on your cutting line. A slight deviation can lead to uneven cuts, so ensure you’re guiding the blade carefully. Avoid working at awkward angles, as this can increase tension and make the cut rough. Once you’ve cut through the aluminum, inspect the edges for any burrs or sharp spots.

To finish up, use a file or sandpaper to smooth out the edges. This ensures safe handling of the cut piece and makes your project look polished. Hacksaws are excellent for those who enjoy a hands-on approach and appreciate precision in their work.

Miter Saw

Cutting extruded aluminum with a miter saw is a popular choice due to its speed and accuracy. First, you need to set the saw at the desired angle if you’re making angled cuts. Ensure the blade is appropriate for cutting aluminum. A carbide-tipped blade generally works best for this purpose to achieve a smooth finish.

Once the saw is set up, secure the aluminum firmly on the base of the miter saw. Use clamps or the saw’s automatic hold-down feature to prevent it from moving during cutting. Before you start the saw, double-check your measurements and align the blade with your cut line. Safety is key, so always wear protective eyewear.

Press the blade down gently to start cutting. Maintain a consistent and controlled motion throughout the process. It’s important to avoid forcing the saw; let the blade do the work. Speeding through the cut can lead to an incomplete job or even injury. Take your time, especially if you notice the aluminum starting to bind against the blade.

Once the cut is completed, lift the blade back to its original position. Inspect the cut edge for any rough spots or burrs. If necessary, file or sand them down for a smoother finish. Miter saws can handle various aluminum thicknesses with ease, making them an excellent tool for larger projects requiring speed and precision.

Be sure to clean the saw afterward, as aluminum shavings can clog the table and affect future cuts. Regular maintenance of all tools extends their life and improves performance, allowing you to cut aluminum safely and efficiently.

Band Saw

When it comes to larger, thicker pieces of extruded aluminum, a band saw is a superior choice. It offers precision and is designed to handle heavy-duty cutting tasks. Start by selecting the right blade. A bi-metal blade with a high tooth count will make short work of your material, giving you clean cuts without much friction.

Before cutting, align your band saw’s cutting table with the blade. Measure the section you need to cut and mark it on the aluminum. Secure the aluminum piece against the fence of the band saw to ensure a straight cut. Remember to don your safety goggles and gloves before starting the machine.

As you start the band saw, adjust the feed rate according to the thickness of the aluminum. For thicker pieces, a slower rate may be necessary. Always keep both hands clear of the blade while maintaining a steady feeding motion. The saw should cut smoothly without force; ease into the feed to minimize the risk of jamming.

Once you finish cutting, wait for the blade to come to a complete stop before removing the aluminum. Be careful of any sharp edges left on the cut piece. Sand or file these down as needed. Band saws are known for producing minimal waste due to their design, so you can count on efficient usage of your aluminum stock.

Lastly, clean up the band saw area after your cutting session. Regularly inspecting the blade for sharpness and wear can improve performance and safety, ensuring your next project runs smoothly.

Table Saw

Using a table saw to cut extruded aluminum can be highly effective for long, straight cuts. Start by equipping the table saw with an appropriate aluminum cutting blade, usually a carbide-tipped blade designed specifically for non-ferrous materials. Ensure your blade is sharp and aligned properly to avoid binding or excessive wear.

Secure the aluminum to the table using clamps or a feather board. This step keeps the material stable during cutting. Take precise measurements and mark the cutting line with a pencil. Before starting the saw, double-check that everything is set up properly. It’s crucial to wear safety goggles and avoid loose clothing when operating power tools.

Once everything is in place, turn on the table saw and feed the aluminum slowly into the blade. Maintaining a steady speed will give you the best results. Rushing through the cutting process can create rough edges and increase the risk of kickback. Keep both hands clear of the blade, and never reach across the cutting area.

After the cut, allow the blade to come to a complete stop before retrieving the aluminum. Examine the cut edge for burrs or sharp sections. Use a file or sandpaper as needed to smoothen these edges for safer handling. A table saw is particularly powerful; it can cut multiple pieces of aluminum quickly and accurately, making it a favorite tool for serious projects.

Finally, remember to clean the table saw and its surrounding area after completing your work. This practice not only keeps your workspace organized but also prolongs the life of your tools. Regular maintenance helps ensure that your table saw remains ready for your next project.

Hand Shears

Hand shears are excellent for quick cuts on thinner sheets of aluminum. They resemble oversized scissors and are perfect for small, intricate cuts. To start, choose a clean, flat piece of aluminum and mark your cutting line with a straight edge. Make sure your mark is clear for more accurate cuts.

Grip the hand shears firmly for control. Position the shears on the marked line and start cutting by applying even pressure. Move slowly and steadily to avoid jagged edges. Hand shears excel in lighter tasks, so they are not suitable for cutting thicker extruded pieces. However, they shine when you need to make quick adjustments or trim edges.

When finished, inspect the edges for any sharp points. If there are rough edges, use a file or sandpaper for a more polished look. Hand shears are a great addition to a DIY toolbox, especially when working with aluminum and other soft metals. They take up little space and are easy to handle.

Always clean your hand shears after use. Removing any aluminum shavings helps maintain their longevity and functionality. Proper storage will keep your hand shears ready for future projects. Hand shears offer an accessible and straightforward answer for those needing occasional cuts on aluminum material.

Step-by-Step Guide to Cutting with Each Tool

Hacksaw

Using a hacksaw for cutting extruded aluminum is a practical choice for smaller projects. First, select a hacksaw blade that is fine-toothed and designed for cutting metal. This type of blade will allow for more precise cuts and reduce the chance of chatter and vibration. Once you have the right blade, measure the section of aluminum you want to cut and mark it clearly with a fine-tipped marker or pencil.

Securely clamp the aluminum in place using a vise or clamps. This prevents movement while you are cutting, ensuring that your cuts are straight and accurate. After you have clamped the material down, hold the hacksaw firmly with both hands. Use slow, steady strokes to saw through the aluminum. Avoid pressing too hard; let the blade do the work. This strategy minimizes the risk of damaging either the blade or the aluminum.

As you cut, keep an eye on your marked line and adjust your angle as necessary. If the saw starts to bind, reduce the pressure and let it cut more freely. Once you’ve cut through the material, remove the aluminum from the vice and inspect the edges. Sharp edges are common when cutting aluminum, so it’s a good idea to file them down. This not only ensures safety but also enhances the appearance of your finished project.

Hacksaws are particularly handy for intricate cuts or when working with smaller aluminum pieces. They allow for close and controlled cuts, making them useful when detail is paramount. While cutting with a hacksaw may take more time than power tools, the precision it offers is unparalleled for smaller tasks. Plus, it’s an affordable tool that doesn’t require any electricity, making it an excellent addition to any DIY toolkit.

Miter Saw

A miter saw is an excellent tool for cutting extruded aluminum, especially when precision and angled cuts are required. This type of saw can make clean, consistent cuts at various angles, which is beneficial for framing projects. To start, make sure you equip the miter saw with a blade that is designed for cutting aluminum. Use a carbide-tipped blade, as it cuts through metal smoothly and lasts longer.

After setting up the saw, measure the piece of aluminum and mark the cut line clearly. Adjust the miter angle as necessary based on your project’s requirements. Once set, secure the aluminum firmly against the saw’s fence to prevent any movement. Double-check the alignment to ensure the blade will meet the marked cut line as planned. Always wear your safety goggles when operating the saw.

As you activate the miter saw, let the blade descend smoothly onto the aluminum. Apply gentle pressure and maintain a steady hand. There’s no need to rush; instead, focus on keeping it steady for a clean and accurate cut. Once you’ve completed the cut, release the blade back to its starting position and retrieve your piece. Check the edges carefully for any rough spots or burrs.

If sharp edges are present, use a file or sandpaper to smooth them out. This additional step is crucial to ensure easier handling and better safety. Miter saws excel in trimming multiple pieces, thanks to their speed and accuracy, making them particularly valuable in professional settings. Whether you’re working on home renovations or detailed projects, a miter saw can significantly elevate your cutting capabilities.

Band Saw

The band saw is a powerful tool ideal for cutting larger sections of extruded aluminum. It features a continuous loop blade that moves in a straight line. One of the key benefits of a band saw is its ability to make smooth, curved cuts as well as straight cuts, depending on the design of the blade. Start by selecting an appropriate blade, typically a bi-metal blade designed for cutting aluminum effectively.

Before you begin, set up the band saw correctly. Ensure that all adjustments are made, including blade tension and alignment. Measure the aluminum and mark the cutting line clearly. After that, adjust the band saw’s speed according to the material thickness—thicker materials require a slower speed for optimal cutting. Always don your safety goggles and gloves before handling the saw.

When you are ready, carefully feed the aluminum into the blade. Keep a steady hand and maintain consistent pressure. The band saw is designed to handle thick materials, but it’s essential to be cautious to avoid binding. If the blade binds or stalls, it may cause uneven cuts or damage the material. Once you have made the cut, wait for the blade to stop before removing the finished piece.

Inspect the cut edge for any burrs or rough areas. If necessary, use a deburring tool or file to smooth the edges, enhancing the safety and look of your piece. Band saws are excellent choices for heavy-duty tasks and can save time on larger projects. They offer precision and reliability, making them a staple in workshops and fabrication shops alike. With the right setup and technique, cutting aluminum with a band saw can be efficient and straightforward.

Table Saw

Cutting extruded aluminum with a table saw is an effective method for achieving straight, long cuts quickly. The table saw provides a stable platform and allows you to work with larger pieces of aluminum with ease. To get started, ensure that your table saw is equipped with a blade specifically designed for non-ferrous metals. A carbide-tipped blade with a high tooth count will provide cleaner cuts with minimal friction.

Before cutting, measure the aluminum piece carefully. Mark the intended cut line precisely, as accuracy is essential for achieving the best results. Adjust the height of the blade to accommodate the thickness of the aluminum. It should be set just above the material to ensure a smooth cut. Once everything is set, secure the aluminum piece against the fence of the table saw to keep it straight during cutting.

Start the saw and gradually feed the aluminum towards the blade at an even speed. Avoid forcing the material into the blade; a steady motion will yield better results and reduce the risk of kickback. Stay aware of your hands and keep them at a safe distance from the blade throughout the process. If you notice any hesitation in the cutting, reduce pressure and allow the blade to do the work instead of forcing it.

After finishing the cut, carefully inspect the edges of the aluminum. Look for any sharp points or burrs that may pose a risk. Taking time to deburr the edges will not only improve safety but also create a more polished look for your project. The table saw is known for its ability to handle multiple cuts efficiently, making it an excellent option for larger tasks.

Lastly, always clean your table saw after use. Proper maintenance, including checking the blade for wear and keeping the workspace tidy, will enhance your cutting experience and prolong the life of your tools. By incorporating proper techniques and precautions, you can enjoy seamless cutting of extruded aluminum with a table saw.

Hand Shears

Hand shears offer a simple yet effective means of cutting thinner sheets of extruded aluminum. These scissors-like tools are particularly useful for smaller projects or when making quick adjustments. To begin, select a flat piece of aluminum and mark your cutting line using a straight edge for accuracy. Ensure the line is well-defined to guide your cutting.

When using hand shears, grip them firmly for control and stability. Position the shears at the beginning of the marked line, ensuring they are aligned correctly. Begin cutting by applying even pressure, moving slowly and smoothly along the line. Hand shears excel at making straight, precise cuts without the need for complex setup or power. The ease of use makes them an excellent choice for quick jobs.

During the cutting process, keep an eye on your angle and pressure. If you pull too hard or cut too quickly, you might create jagged edges. Once you have finished the cut, inspect the aluminum for any sharp edges left behind. It’s essential to smooth these edges using a file or sandpaper to ensure safe handling of your finished piece.

Hand shears are particularly handy for DIY enthusiasts and crafters. They are lightweight and take up little space, making them easy to use and store. While they may not be suitable for cutting thicker aluminum profiles, they shine in situations that demand simple solutions for lighter tasks. This versatility and accessibility make them a staple in most toolboxes.

Finally, remember to clean the blades of your hand shears after use. Aluminum particles can accumulate and potentially affect performance. Keeping your tools in good condition will ensure reliable performance for all your future projects. Hand shears may seem simple, but with the right approach, they can provide precise cuts that fuel your creative endeavors.

FAQs

What type of blade should I use to cut extruded aluminum?

When cutting extruded aluminum, it’s best to use a blade designed specifically for non-ferrous metals. A carbide-tipped blade with a high tooth count is ideal, as it will provide a smoother cut and have a longer lifespan. For hacksaws, choose a fine-toothed blade to minimize chatter and ensure precision.

Can I use the same tools for cutting aluminum and wood?

While some tools can cut both aluminum and wood, it’s essential to use the appropriate blades for each material. Using wood blades on aluminum can lead to poor cuts and blade damage. Always select blades specifically designed for cutting aluminum to achieve cleaner results and maintain tool integrity.

What safety gear should I wear when cutting aluminum?

When cutting aluminum, you should always wear safety goggles to protect your eyes from flying debris and metal shavings. Additionally, consider using gloves for hand protection and a dust mask to avoid inhaling aluminum dust. Wearing closed-toed shoes, preferably steel-toed, can also protect your feet during heavy lifting and cutting tasks.

How can I achieve a clean cut when using a hacksaw?

To achieve a clean cut with a hacksaw, ensure that you use a fine-toothed blade specific for metal cutting. Secure the aluminum firmly in place and use steady, even strokes while cutting. Avoid pushing too hard; instead, let the blade do the work. Finally, clean up any burrs with a file or sandpaper after completing the cut.

Is it necessary to deburr the edges after cutting aluminum?

Yes, deburring the edges after cutting aluminum is essential for safety and aesthetics. Sharp edges can pose a risk of cuts and injuries. Use a file or sandpaper to smooth out any rough areas. This practice not only makes handling the aluminum safer but also improves the overall appearance of your finished project.

Can I cut thick aluminum profiles with a miter saw?

Absolutely. A miter saw is well-suited for cutting thick aluminum profiles, provided it is equipped with the appropriate metal cutting blade. Ensure you secure the material properly and take proper safety precautions. With the right setup, a miter saw can deliver precise cuts, including various angles needed for your project.